Heat Exchangers Main Parts and TEMA Type YouTube

This video is a continuation from Episode 1, a comparison of the design differences between TEMA Class R, Class C and Class B heat exchangers. The basis for.

TEMA Type Shell & Tube Heat Exchanger by COSMEC s.r.l. Energy Dais

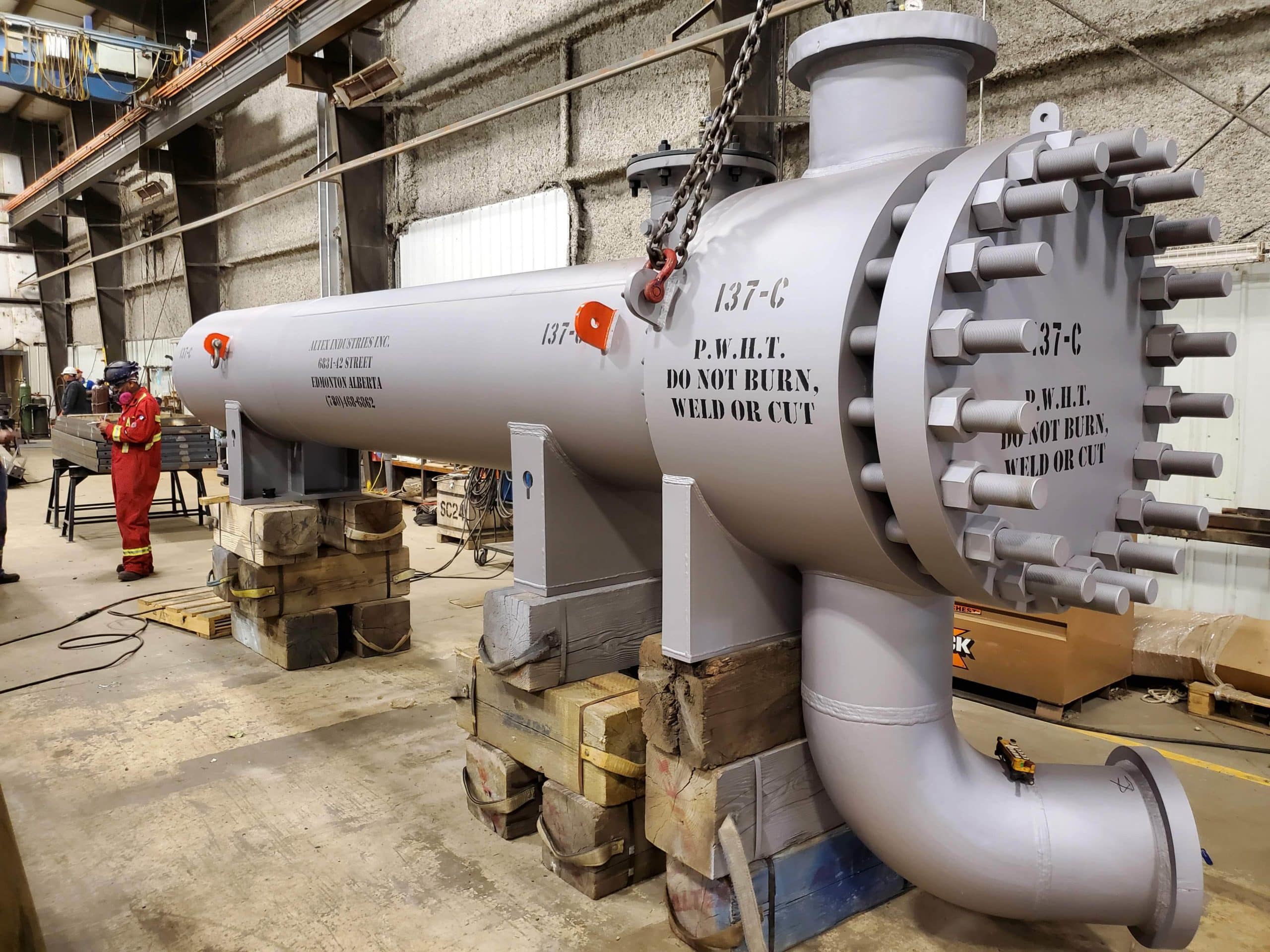

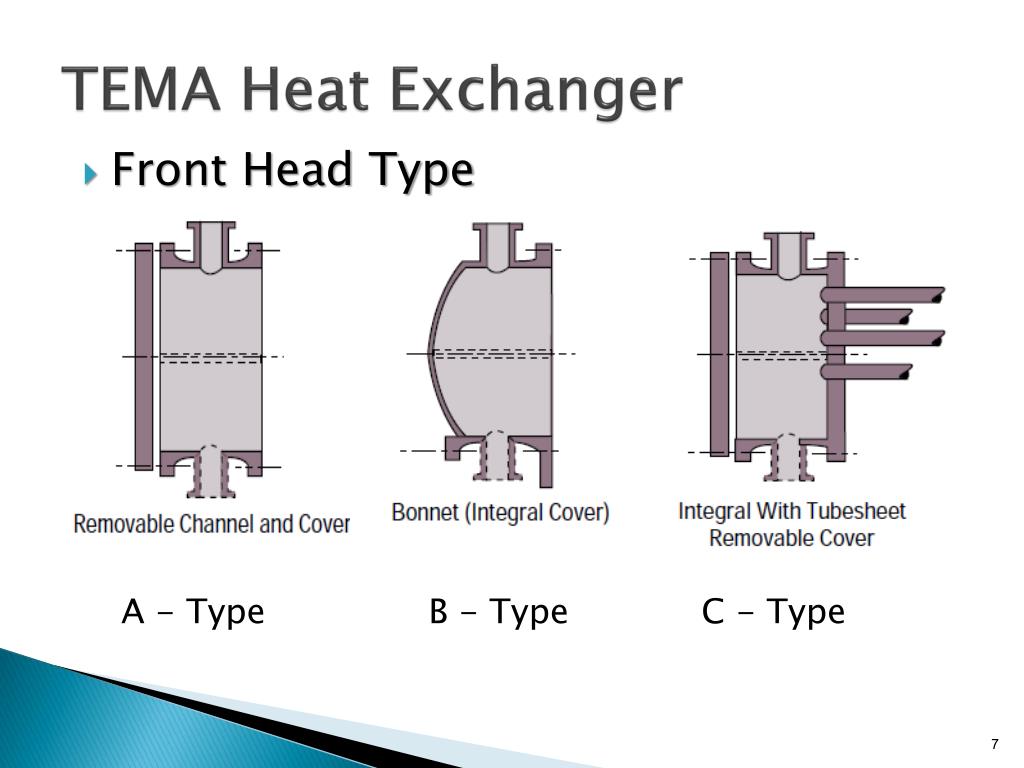

Some examples of the TEMA designation for Heat Exchangers. BEM. Bonnet (Intergral Cover), One Pass Shell, Fixed Tubesheet Bonnet. Fixed tubesheet heat exchanger. This is a very popular version as the heads can be removed to clean the inside of the tubes. The front head piping must be unbolted to allow the removal of the front head, if this is.

Industrial Heat Exchangers Explaining ASME, API, and TEMA

NOTE: the following items may be reproduced without permission, as long as TEMA is cited as the source. -Figure N-1.2 (Table of TEMA types)-Table N-2 and Figure N-2 (Nomenclature)-Figure G-5-2 (Heat Exchanger Spec Sheet - English Units) PDF XLS-Figure G-5-2M (Heat Exchanger Spec Sheet - Metric Units) PDF XLS. 4

AF Series Heat Exchangers TEMA Type BEM, BEL, NEN RP Adams

TEMA (Tubular Exchangers Manufacturing Association) is the preferred standard for the manufacture of shell and tube heat exchangers. The general descriptions of the three major TEMA classes are: TEMA C - General Service. TEMA B - Chemical Service. TEMA R - Refinery Service. TEMA R is the most demanding standard, while TEMA C is the least.

Popular TEMA Shell and Tube Heat Exchanger Types explained with Graphics and Animation Heat

6.4.1 TEMA Types. TEMA standards cover the heavy-duty heat exchangers (TEMA R) as well as the lighter duty heat exchangers (TEMA C and TEMA B). Refineries typically use only the TEMA "R" heat exchangers due to the generally severe requirements of petroleum applications; however, more moderate process services may warrant consideration of TEMA B construction.

Heat Exchanger construction TEMA types Details 2CH301 Heat Transfer Operations

This video is a comparison of the design differences between TEMA Class R, Class C and Class B heat exchangers. The basis for this commentary is Section 5 o.

PPT Heat Exchangers Design and Construction PowerPoint Presentation, free download ID4901853

TEMA heat exchangers are shell and tube heat exchangers built to manufacturing standards laid out by the Tubular Exchanger Manufacturers Association (TEMA). TEMA regulations define the style of heat exchangers and the machining and assembly tolerances. As the default, TEMA would be used in conjunction with the design industry code.

TEMA Heat Exchangers

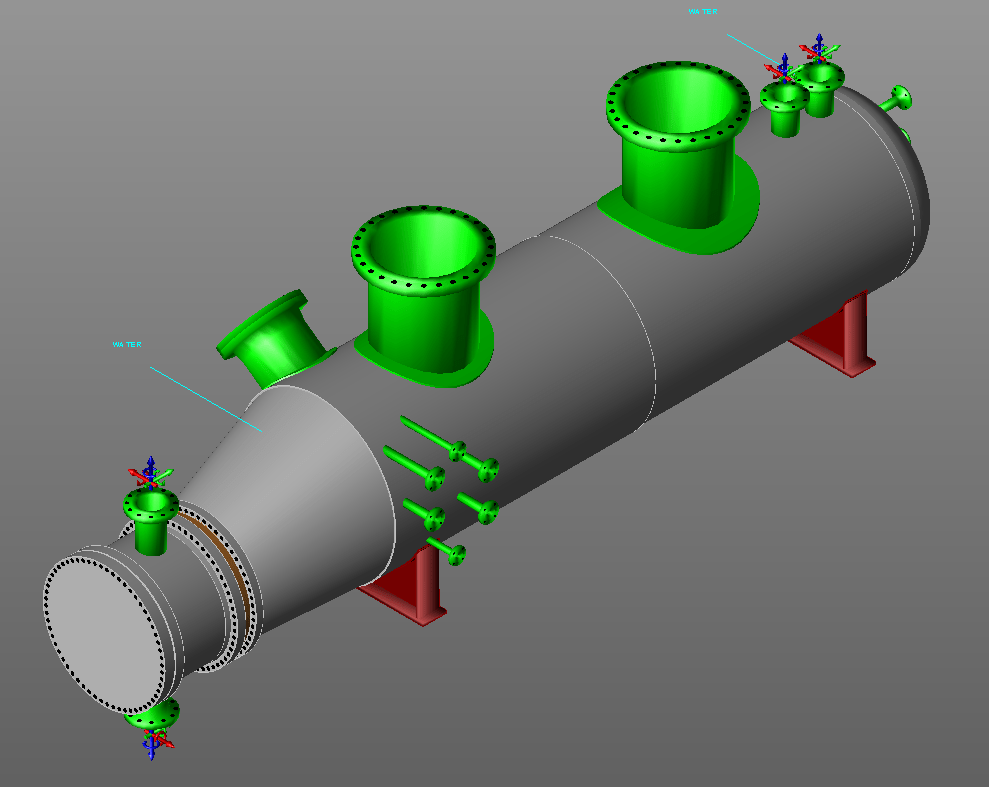

Overview. Product Features. TEMA type AEL, BEM or NEN. Fixed bundle. Straight tube. Less costly than removable straight tube bundle designs. Straight Tube, Fixed tubesheet with removable channel or bonnet or integral channel with removable cover. Can meet all TEMA classes as well as ASME Section VIII Div 1 and ASME Section III N stamp for Nuclear.

TEMA AES heat exchanger 3D CAD Model Library GrabCAD

heat exchangers specify design and fabrication of unfired shell and tube heat exchangers for the generally moderate requirements of commercial and general process application. "Class C" units are designed for maximum economy and result in a cost saving of about 5% over "Class R". TEMA "Class B" exchanger - The TEMA Mechanical Standards for.

AR Series Shell and Tube Heat Exchanger TEMA Type AEW, AET, BEP, AES RP Adams

See TEMA Paragraph N-1.11 for determining the nominal shell diameter. In the case of shell inside diameters with fractions of 12.7 mm(.5 inch) and less it is acceptable to round down to the nearest integer. RCB-3.13 (326) Minimum thickness requirement fro Carbon Steel from 30-100 Inch -12.7 mm which is very stringent.

TEMA Heat Exchangers A Comprehensive Guide

TEMA stands for "Tubular Exchangers Manufacturers Association" and is a set of standards that were developed by leading shell and tube manufacturers. These standards define the style of heat exchanger and the machining and assembly tolerances. One of the advantages of selecting a shell & tube manufacturer that builds to TEMA specifications is that the end-user is assured that they will.

Brief Introduction To TEMA HEAT EXCHANGERS Design And Selection CADE Engineered Technologies

TEMA Classifications of Heat Exchangers TEMA's standard recognizes three separate classifications of exchangers[9][10][11]. Each class has different mechanical construction requirements, based on the expected service. Those classes are: Class R - for refinery and petroleum service Class C - for general commercial service

TEMA designations for shell and tube heat exchangers. Download Scientific Diagram

TEMA type is how most shell and tube heat exchangers are defined. By assigning a TEMA type, anyone can have a quick understanding of the heat exchanger's general configuration, diameter, and length. The type is defined by using three letters in series (eg, BEU, NEN, or AES). The first letter will define the front head (channel) and is.

TEMA Shell & Tube Heat Exchanger Bronswerk Heat Transfer

A shell and tube heat exchanger is a device used in the thermal management of a process, which is used to transfer heat between two fluid streams. The exchanger device is made up of a shell, channel (s)casing, tube bundle tube, or flow path. The shell and channel are is typically made of carbon or stainless steel metal, with the tube being.

Comparison of TEMA R, C, & B Heat Exchangers Episode 2 YouTube

The general principles of the mechanical design of the following types of exchangers are given in the Heat Exchanger Design Handbook (1994), and full descriptions of each, are given under the corresponding entries in this encyclopedia: Shell and Tube Exchangers. Air Cooled Exchangers. Plate Type Exchangers. Plate Fin Type Exchangers.

Tema exchanger types onthewebaceto

CADE Engineering Contact. +34 967 19 01 72. TEMA Standards are worldwide accepted as the authority on shell and tube heat exchangers design and manufacturing. These standards are the most commonly used in a wide range of industries throughout the world: refineries, oil and gas, power generation, etc.

.